Project Description

Why attend

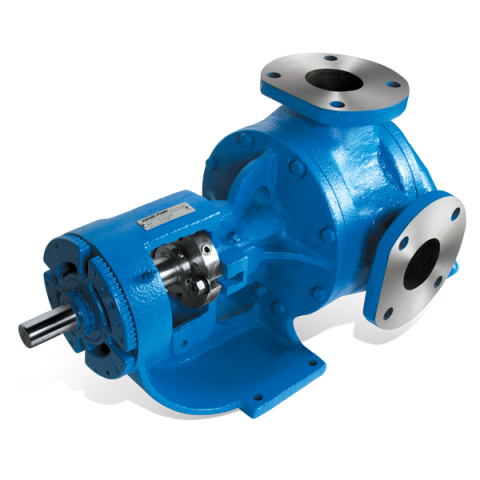

The course is designed to provide an in-depth perspective of pump technology in terms of selection, operation, maintenance and repair. Topics covered include pump types and terminology, centrifugal and positive-displacement pumps, packing, mechanical seals and sealing systems, bearings, couplings and other vital components.

The course will provide participants with a complete and up-to-date knowledge of pumps and their systems. Further, participants will learn more about selection, operation and maintenance strategies which will assist in increasing pump availability and reliability. Upon the completion of this course, participants will be able to troubleshoot all types of pump problems.

Course Objectives

By the end of the course, participants will be able to:

Apply proper techniques in selection, installation, operation, maintenance and troubleshooting of various types of pumps used in process industry.

Maintain and troubleshoot all types of pumps including the failure analysis and troubleshooting of packing and mechanical seal.

Properly maintain pump bearings and describe the importance of couplings and alignmen.

Implement the maintenance and reliability programs to analyze and minimize pump costs and improve its reliability.

Who should attend

This course provides an overview of all significant aspects and considerations of pumps and valves in accordance with the international standards for those who are involved in the sizing, selection, operation, inspection, maintenance and troubleshooting of pumps. This includes process engineers, mechanical engineers, piping engineers, pipelines and pressure vessels engineers and supervisors.

Course Outline

- Pumps

- Pump Terminology

- Nomenclature and Definitions

- Pump Types

- Pump Operation & Theory

- Centrifugal Pump Theory ,

- Pump Characteristic Curves ,

- Operating Characteristics ,

- Centrifugal Pump Operation ,

- Cavitation and NPSH ,

- Elements of Minimum Continuous Safe Flow (MCSF) ,

- How to Calculate MCSF ,

- Types of Centrifugal Pumps ,

- Design Aspects of Centrifugal Pumps

- Parts of Centrifugal Pumps,

- Bearing Basics,

- Balancing Criteria,

- Installation and Start-up,

- Performance Comparisons,

- Troubleshooting Centrifugal Pumps,

- Inspecting Centrifugal Pump Components for Wear,

- Centrifugal Pump Overhaul,

- Centrifugal Pump Maintenance & Troubleshooting

- Reciprocating Pumps,

- NPSH Requirement for Reciprocating Pumps,

- Rotary Pump Theory and Operation,

- PD Pumps in the Operating System,

- How to Select Progressing Cavity Pumps

- Reciprocating (Power) Pumps,

- Rotary Gear Pumps,

- Screw Pumps,

- Operation,

- Reciprocating (Power) Pump Liquid End Maintenance,

- Reciprocating Pump Valve Repair

- Compression Packing,

- Moulded (Automatic) Packing,

- Basic Principles of Mechanical Seals,

- Face Materials,

- Secondary Seal Materials,

- Single Mechanical Seals,

Mechanical Seal Failure Analysis and Troubleshooting

Bearing Care and Maintenance

Couplings and Alignment

Pump Maintenance and Reliability

The workshop

This interactive training course includes the following training methodologies as presented on the next column based on percentage of the total tuition hours:

Lectures

Workshops & Work presentation

Case Studies & Practical Exercises

Videos, Sofware & General Discussion

The course instructor may modify the above training methodology before or during the course for technical reasons with no prior notice to participants.

Falcon Consulting Professionals is established in Greece for the last 15 years in the areas of technical consulting and professional training for the local industries. Falcon is expanding in GCC, aiming to provide the best consulting and training solutions to the industries of the region. Falcon’s instructors are accredited trainers and highly experienced in their fields, as well as adult training. We aspire to build our business relationships on mutual trust. The achievement of results with an emphasis on innovation and sustainability, quality, cost analysis and time scheduling are non-negotiable from the conceptual phase of the training.