Project Description

Why attend

This course is created to provide a complete understanding of the various types of motors, variable-speed drives, transformers, generators, rectifiers and inverters, uninterruptable power systems (UPS), circuit breakers, and fuses. Once successfully completed, delegates will be able to identify, select, commission and maintain these equipment for their applications. Additionally, delegates will have sufficient information to achieve reduced capital, operating and maintenance costs along with increased efficiency.

Course Objectives

By the end of the course, participants will be able to:

Identify, select, install, operate, test, troubleshoot and maintain various types of electrical equipment such as transformers, motors, variable speed drives, generators, circuit breakers, switchgears and protective systems.

Apply diagnostic testing and inspection, advanced fault detection techniques, critical components, and common failure modes for electrical equipment.

Employ selection criteria, commissioning requirements, predictive and preventive maintenance, reliability, testing and cost estimation for electrical equipment.

Apply maintenance techniques required to minimize the operating cost and maximize the efficiency, reliability and longevity of electrical equipment.

Who should attend

This course provides an overview of all significant aspects and considerations of electrical equipment including transformers, motors, variable speed drives, generators, circuit breakers, switchgears and protective systems. It’s suitable for engineers and other technical staff who are involved in the selection, installation, operation, testing, troubleshooting or maintenance of such electrical equipment.

Course Outline (Not inclusive)

- Capacitors – Current and Resistance – The Magnetic Field –

- Faraday’s Law of Induction – Lenz’s Law – Inductance –

- Alternating Currents – Three-Phase System

- Electric Machines and Transformers – Common Terms and Principles –

- The Magnetic Field – Magnetic Behavior of Ferromagnetic Materials –

- Faraday’s Law –

- Importance of Transformers – Types and Construction of Transformers –

- The Ideal Transformer – Impedance Transformation Through a Transformer –

- Analysis of Circuits Containing Ideal Transformers –

- Introduction, Classification of Transformers – Main Components of a Power Transformer –

- Types and Features of Insulation – Forces – Cause of Transformer Failures –

- Transformer Oil – Gas Relay and Collection Systems-

- Relief Devices – Interconnection with the Grid

- The Rotating Magnetic Field – The Induced Voltage in AC Machines –

- The Induced Torque in a Three-Phase Machine –

- Winding Insulation in AC Machines –

- AC Machine Power Flow and Losses

- Induction Motor Construction –

- Basic Induction Motor Concepts –

- The Equivalent Circuit of an Induction Motor –

- Losses and The Power-Flow Diagram –

- Speed Control by Changing the Line Frequency –

- Speed Control by Changing the Line Voltage –

- Speed Control by Changing the Rotor Resistance –

- Solid-State Induction Motor Drives – Motor Protection –

- Introduction to Power Electronics – Power Electronics Components –

- Power and Speed Comparison of Power Electronic Components –

- Basic Rectifier Circuits – Filtering Rectifier Output –

- Pulse Circuits – A Relaxation Oscillator

- Basic Principles of AC Variable Speed Drivers (VSD’S) – Inverters – Input Power Converter (Rectifier) –

- DC Link Energy – Output IGBT Inverter, Input Sources for Regeneration or Dynamic –

- Regeneration – PWM-2Considerations – Transients –

- Harmonics Power Factor and Failures -Thyristor Failures and Testing

- Physical Description – Pole Pitch: Electrical Degrees –

- Airgap and Magnetic Circuit of a Synchronous Machine –

- Synchronous Machine Windings – Field Excitation –

- No-Load and Short-Circuit Values – Torque Tests –

- Excitation of a Synchronous Machine – Machine Losses

- Synchronous Generator Construction –

- The Speed of Rotation of a Synchronous Generator –

- The Internal Generated Voltage of a Synchronous Generator –

- The Equivalent Circuit of a Synchronous Generator –

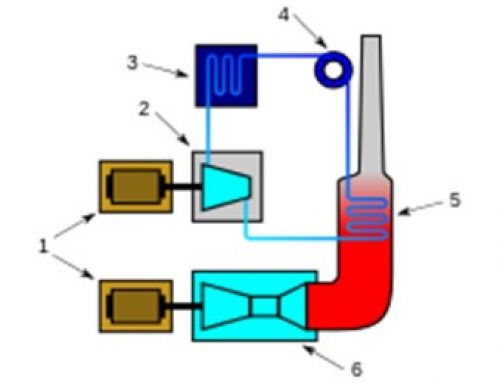

- Introduction, The Rotor, Turbine-Generator Components, Cooling Systems,

- Shaft Seals and Seal Oil Systems, Stator Winding Water Cooling Systems,

- Other Cooling Systems, Excitation, The Voltage Regulator,

- The Power System Stabilizer,

- Characteristics of Generator Exciter Power Systems (GEP), Generator Operation

- Introduction – Isolated Phase Bus Bar Circulatory Currents –

- System Description

- Generator Systems – Condition Monitoring – Operational Limitations -Fault Conditions

- Generator Operational Checks (Surveillance and Monitoring) –

- Generator Diagnostic Testing – Insulation Resistance and Polarization Index –

- DC Hipot Test – AC Tests for Stator Windings –

- Synchronous Machine Rotor Windings –

- On-Load Maintenance and Monitoring – Off-Load Maintenance – Generator Testing

- Typical Generator Operational Problems –

- Generator Rotor Reliability and Life Expectancy –

- Generator Rotor Refurbishment – Types of Insulation –

- Generator Rotor Modifications –

- Upgrades and Uprates – High Speed Balancing – Flux Probe Test

- Theory of Circuit Interruption – Physics of Arc Phenomena –

- Circuit Breaker Rating – Conventional Circuit Breakers –

- Methods for Increasing Arc Resistance – Plain Break Type –

- Magnetic Blow-out Type – Arc Splitter Type – Application –

- Oil Circuit Breakers – Recent Developments in Circuit Breakers

- Types of Fuses – Features of Current Limiting Fuses – Advantages of Fuses Over Circuit Breakers

- Types of Bearings – Statistical Nature of Bearing Life –

- Materials and Finish- Sizes of Bearings –

- Types of Roller Bearings – Thrust Bearings

- Used Oil Analysis Proper Lube Oil Sampling Technique –

- Test Description and Significance –

- Visual and Sensory Inspection –

- Chemical and Physical tests

- The Application of Sine Waves to Vibration – Multimass Systems –

- Resonance- Logarithms and Decibels (db) – The Use of Filtering –

- Vibration Instrumentation – Time Domain –

- Electrical System Description -System Performance –

- Power Plant Outages and Faults –

- Uninterruptible Power Supply (UPS) Systems – DC Systems

- Introduction –

- Design Criteria –

- Generator Protection –

- DC Tripping Systems

The workshop

This interactive training course includes the following training methodologies as presented on the next column based on percentage of the total tuition hours:

Lectures

Workshops & Work presentation

Case Studies & Practical Exercises

Videos, Sofware & General Discussion

The course instructor may modify the above training methodology before or during the course for technical reasons with no prior notice to participants.

Falcon Consulting Professionals is established in Greece for the last 15 years in the areas of technical consulting and professional training for the local industries. Falcon is expanding in GCC, aiming to provide the best consulting and training solutions to the industries of the region. Falcon’s instructors are accredited trainers and highly experienced in their fields, as well as adult training. We aspire to build our business relationships on mutual trust. The achievement of results with an emphasis on innovation and sustainability, quality, cost analysis and time scheduling are non-negotiable from the conceptual phase of the training.