Project Description

Why attend

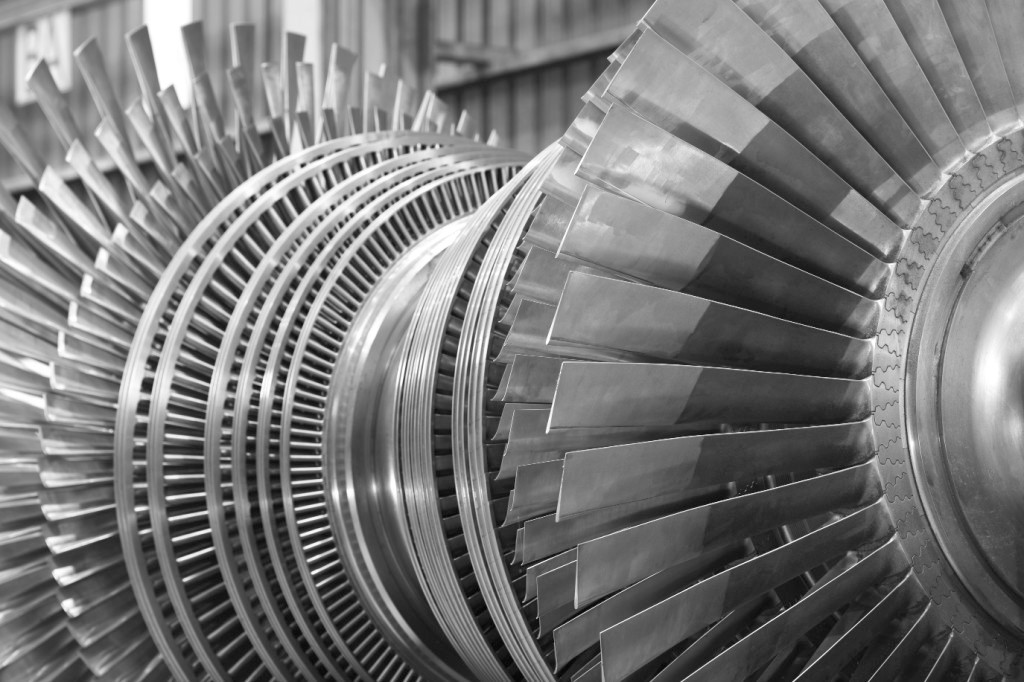

The course is designed to provide an in-depth perspective of steam and gas turbine, co-generation/ combined cycle plants technology in terms of theory of operation, selection, practical operation. Topics covered include steam and gas turbines terminology, rotor dynamics, blade (bucket) design, burners (GT), housings, materials of construction, shafts, bearings, seals, generators, HSRGs, auxiliary systems, and control systems.

Other topics include extensive theory on operation of combined cycle gas plants, plant types, fuel types, gas engines, recovery boilers, water steam cycle, electrical systems etc.

Course Objectives

By the end of the course, participants will be able to:

Identify the different Gas and Steam turbine components which include turbine rotors, balancing, rotor dynamics, casings, bearings, shaft sealing devices and lube oil management

Identify the construction, support & auxiliary systems as well as the mechanical maintenance of the gas turbine generator.

Explain in detail the mechanical design, configurations, application ranges and constraints for steam turbines.

Perform the selection and sizing of steam turbines for compressor and generator drives and recognize the operation and management of steam turbines.

Understand the basic design/diagrams and operation of combined cycle and cogeneration plants. Understand efficiency issues and requirements for each type.

Emphasize on the requirement of each component of the plant type, turbines, recovery boilers, generators, steam cycles, heat recoveries, electrical and auxiliary systems, as well their operation in the most practical way.

Who should attend

This course provides an overview of all significant aspects and considerations of cogeneration and combined cycle plants and especially their main parts, gas and steam turbines in accordance with the international standards for all professionals involved in the sizing, selection, operation, inspection, of gas and steam turbines. This includes process engineers, mechanical and electrical engineers, supervisors and operators.

Course Outline

- Gas Turbine Basics – Gas Turbine Construction and Parts- Gas Turbine Device Summary – Gas Turbine Instrumentation (function and maintenance) – Gas Turbine-Generator Arrangement.

- Operating and Maintenance Factor Considerations – Standard Practices. – Gas Turbine Support Systems: Description, Maintenance & Troubleshooting

- Trip Oil – Cooling Water – Cooling and Sealing Water

- Fuel Systems – Gas & Liquid – Atomizing Air – Purge Air

- Water Injection – Heating and Ventilation

- Fire Protection – Hazardous Gas

- Operating Principles & Mechanical Design – Impulse Turbines – Reaction Turbines

- Application and Ranges – Configurations – Application Constraints

- Turbine Components

- Turbine Rotors – Blading – Diaphragms – Nozzles – Steam Chests – Glands and Gland Systems – Bearings, Balancing – Rotor Dynamics – Governing Systems – Lube Oil Management

- Selection and Sizing of Steam Turbines for Compressor Drives, Steam (Water) Rates – Condensing and Backpressure Turbines – Single and Multistage Types – Process Considerations

- Operation and Maintenance of Steam Turbines

- Commissioning – Startup – Run-In and Shut-down – Surveillance and Health Monitoring – Performance Measurement – Monitoring and Tracking

- Operation principles, Main parameters of cogeneration plants, Environmental Impact, Regulatory frameworks.

- Types of cogeneration plants, Fuel types. Gas Engines, Recovery Boilers, Water Steam Cycle.

- Electrical, Control and Auxiliary Systems.

- Functional diagram

- Types of combined cycle power plants

- Characteristic parameters

- Rankine Cycle

- Types of boiler, Horizontal and vertical HRSG

- Reboiler, Economizers, evaporators, superheaters, reheaters.

- Temperature control

- Safety valves

- Electrical, Control and Auxiliary Systems of Cogeneration Plants

The workshop

This interactive training course includes the following training methodologies as presented on the next column based on percentage of the total tuition hours:

Lectures

Workshops & Work presentation

Case Studies & Practical Exercises

Videos, Sofware & General Discussion

The course instructor may modify the above training methodology before or during the course for technical reasons with no prior notice to participants.

Falcon Consulting Professionals is established in Greece for the last 15 years in the areas of technical consulting and professional training for the local industries. Falcon is expanding in GCC, aiming to provide the best consulting and training solutions to the industries of the region. Falcon’s instructors are accredited trainers and highly experienced in their fields, as well as adult training. We aspire to build our business relationships on mutual trust. The achievement of results with an emphasis on innovation and sustainability, quality, cost analysis and time scheduling are non-negotiable from the conceptual phase of the training.